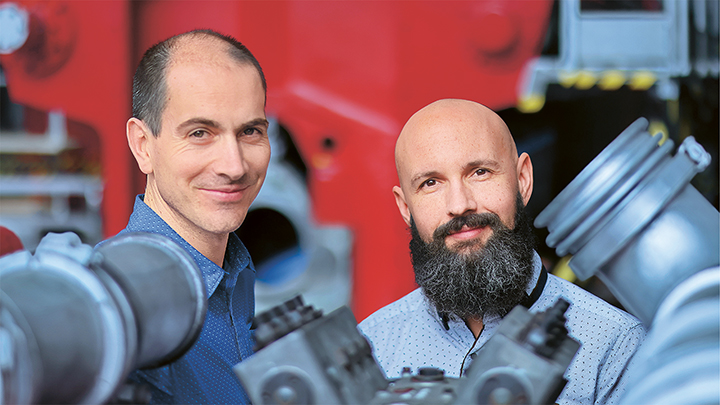

MAN Energy Solutions has been pursuing concrete climate goals for its production sites for many years already. Christoph Zeppenfeld and Dietmar Pinkernell explain where we are now and what is planned for the period up to 2030.

MAN People: Where do we currently stand with regard to decarbonization and climate protection as far as the production sites are concerned?

Dietmar Pinkernell: We have achieved a great deal. We use energy-efficient machines and new technologies, for example. When it comes to the buildings, we have invested in insulation, lighting and air conditioning. We have also made a good many testbed savings thanks to various technical improvements and optimized processes. And in Europe all of our electricity comes from renewable sources.

Christoph Zeppenfeld: The energy and carbon figures for the last two years are also affected by our capacity utilization and the high proportion of mobile working, of course. But even against this background we have achieved a lot in recent years.

What are our climate goals for 2030?

Zeppenfeld: We want to cut our own carbon emissions by another 50 percent compared with 2018. At the same time, we will also make our own contribution to energy generation from renewable sources. Aside from energy and carbon, we have also been pursuing other environmental goals, such as VOC emissions and water consumption, for many years now. Being careful with water will become even more important in the next few years.

We want to cut our own carbon emissions by another 50 percent compared with 2018.

What are the biggest levers when it comes to achieving our goals in the next eight years?

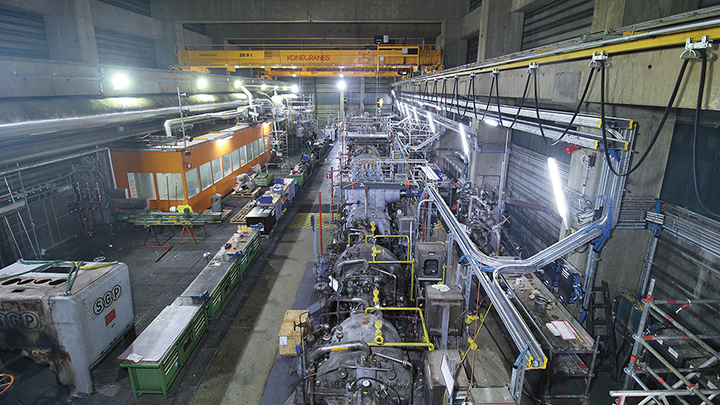

Zeppenfeld: Although we have already optimized our testing and acceptance procedures, we need to take action in this area in particular. The testbeds represent around 20 percent of our total carbon emissions. A further reduction is only possible by getting away from fossil fuels. In other words, the more carbon-neutral products we sell, the more our own emissions will fall too. That is because we have to test the products we sell in accordance with current rules, of course. So we can only achieve a further reduction together with the Front End, Engineering and the Product Lines.

Pinkernell: At the end of the day, every little bit helps when it comes to achieving our ambitious goals. As I see it, in light of costs and security of supply, the expansion of self-generation is also important. We have already taken steps in this respect and there are more to come.

Christoph Zeppenfeld and Dietmar Pinkernell explain which fuels engines on the testbeds in Augsburg can run on to MAN People editor Dagmar Rohe

Are there obstacles too?

Pinkernell: Our infrastructure makes for challenges in some places. Many existing buildings have large roof surfaces that at first glance seem perfect for solar power systems. But they often cannot take the weight and the cost of installation would be so high that the whole thing is not yet worth it.

Zeppenfeld: It is also important for us to think across sites, make optimum use of our money and capacities, and seek out the most economical implementation options.

How can employees contribute?

Pinkernell: As already mentioned, every little bit helps. Just like at home, the aim is to save energy, which means turning off lights, monitors, heating and air conditioning when you leave the office. Other options include car sharing and using public transport. Although I will not see this saving in the figures for our sites, the environment will thank us for it.

Zeppenfeld: At the same time, increases in productivity also generally result in an improved CO2 balance. And the contribution made by quality improvements should not be underestimated either, as in the final analysis scrapping is simply a waste of energy and resources. So it is not just our customers and operating result that appreciate optimum quality, but the environment too.

Explore more topics

-

Short response times low emissions

Gas power plants can provide backup for renewable energies, yet investments in this type of energy generation have faltered in recent years. What are the reasons for this and how will the market evolve?

-

Obsolescence logged off

Obsolescence poses a major challenge for industry going forward, threatening to test the limits of equipment durability and customer satisfaction.

-

Race against time

With the major overhaul carried out as part of the turnaround at the Schwechat Refinery, MAN Energy Solutions once again demonstrates its organizational talent in the cross-functional project management.

-

A record year for the screw compressor

MAN ES is enjoying a particularly strong year for process gas screw compressors (PGSCs). Increasing localization is strengthening our market position.

-

Entering uncharted technological territory

Implementation of the BREVICO project presents no shortage of physical and technical challenges. It is a good thing that interrelationships can be grasped in advance using dynamic process simulations.

-

Small reactor, big success

In December 2022, Barbara Frenkel and Michael Steiner of Porsche’s Executive Board turned on the ‘Haru Oni’ e-fuel pilot plant in Chile. MAN Energy Solutions is involved in this prestigious project too.