Obsolescence poses a major challenge for industry going forward, threatening to test the limits of equipment durability and customer satisfaction.

Obsolescence monitoring at MAN ES is based on a system of classifying components into one of three grades – low, moderate, or high – according to their durability. This makes it possible to anticipate risks of obsolescence in the short, medium, and long term. With the need to strengthen supply chains in mind, this approach also goes beyond just components sourced from suppliers to cover raw materials and the various stages of production too. When it comes to preparing for aging-related issues in the Pielstick engine fleet, proactive intervention is crucial. Without it, there is a danger that facilities will have to be shut down permanently, thus reducing demand for spare parts and impacting on after-sales service revenue. What needs to be done is to identify strategic systems, assess the risks involved, and set up a monitoring program to manage obsolescence.

My role is to anticipate risks by identifying key components and technologies likely to become obsolete. I consult with external suppliers to ensure parts availability and life of parts. As part of a collaboration, I work closely with various departments within the company to collect the information required for this

monitoring.

Keeping watch on the one hand, while taking action on the other

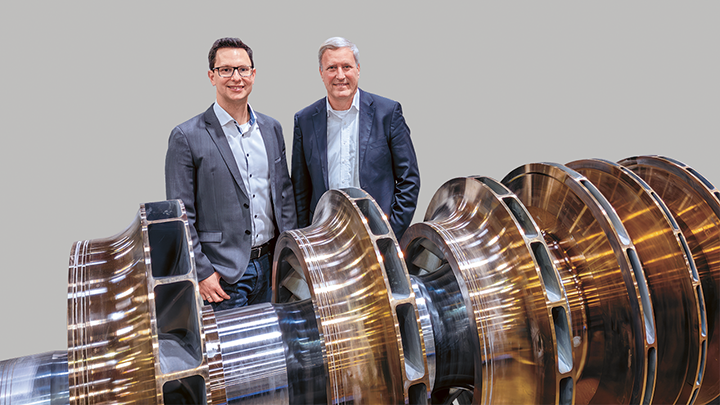

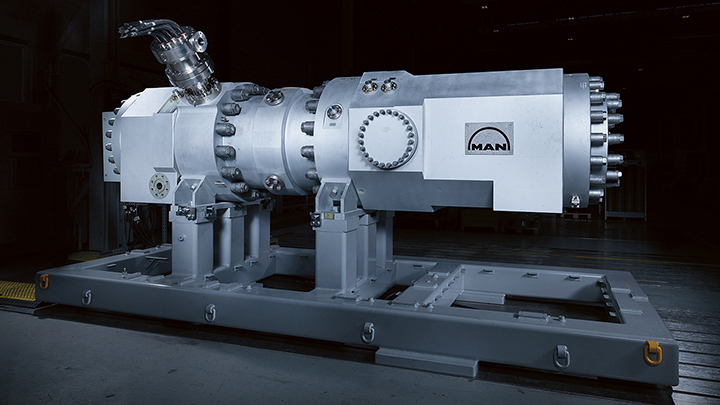

Guillaume Roy is in charge of monitoring the obsolescence of the Pielstick engines produced at MAN ES France, which are used across the globe in a range of applications – including power plants, nuclear emergency units, and marine propulsion systems: “After 14 years at PrimeServ, I was given the task of setting up the obsolescence unit and have been developing my expertise in proactive monitoring. My role involves anticipating risks by identifying key components and technologies that are susceptible to becoming obsolete. I liaise with external suppliers to ensure the availability and useful life of parts. Internally, through a collaborative process, I work closely with various departments across the organization to get the information I need to implement this monitoring system.

Alexandre Larguier, an engineer by training who has a background in the automotive industry, joined MAN ES in 2018 to provide services to the Engine Research and Development department before being brought in to bolster the obsolescence management team in 2023: “My expertise is in managing the proactive handling of obsolescence in strategic items identified through monitoring. It is still possible to take a reactive approach should any urgent needs arise in relation to particular projects or PrimeServ. I work with various departments, including R&D, Purchasing, Quality, and Sales.” Alexandre also highlights his role as a project manager: “At any one time, I could be dealing with thirty or so requests relating to anything from machined parts to complete sub-assemblies, which calls for coordination between different units within the organization.”

Consolidating our pioneering position

In the three years since MAN ES France struck up a partnership with the IIOM (International Institute of Obsolescence Management) and the IFO (Institut Français de l'Obsolescence – French Institute of Obsolescence), the organization has found itself thrust to the forefront of the industrial scene, alongside leading names within the sector and both existing and prospective customers. By playing an active part in international conferences, we have been helping to stimulate dialog on best practices and encourage collective thinking. Alongside this, we have been involved in creating the “POP” Master’s degree program (“POP” stands for “Pérennité, Obsolescence, Pénurie,” which translates as “Durability, Obsolescence, Shortage”) in collaboration with the mechanical engineering school ISAE-Supméca – securing the future by passing on the baton to the next generation!

A boost for sovereignty and sustainability

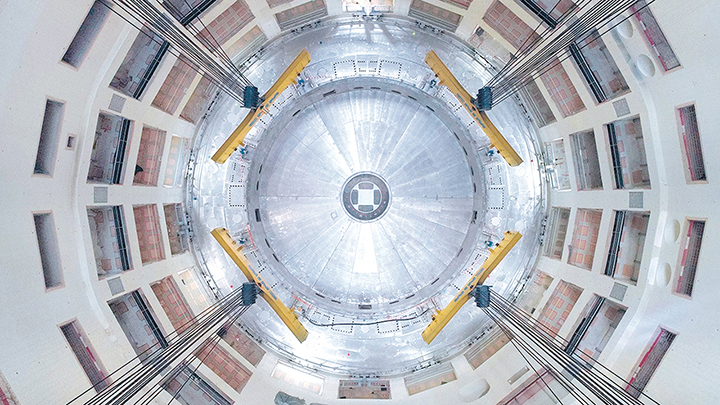

In situations like sensitive naval applications or nuclear emergency units, where the useful life of Pielstick engines is critical, proactive obsolescence management becomes a strategic factor too. By guaranteeing that parts will be available, MAN ES helps to ensure the security of facilities and the longevity of engines in key sectors – and, as a result, helps to maintain national sovereignty.

Adapting to technological developments and environmental issues

The challenges posed by obsolescence also present potential opportunities for modernization and standardization. New technologies such as additive manufacturing and 3D scanning, for example, are options that have already been tried and tested. Moreover, as part of wider efforts to adopt more environmentally conscious solutions, obsolescence management is an essential tool for making sure our products comply with increasingly stringent environmental protection regulations such as REACH and France’s IPCE system.

Explore more topics

-

Sustainable ammonia production

Ammonia can play a key role in decarbonization as a fuel and hydrogen carrier – MAN ES is very much at home with this chemical base material.

-

Sustainable fuels at competitive prices

A German startup wants to help cut carbon emissions in the mobility sector and is relying on the expertise of MAN Energy Solutions in Deggendorf to achieve its objective.

-

Engineering United

Cooperation between Holeby, Frederikshavn, Augsburg and Copenhagen crucial for the development of methanol genset.

-

Investment in testbeds

In a few years, our engines will be running on fuels like methanol and hydrogen, so we are already preparing our testbeds for the change.

-

Climate-neutral district heating for Denmark

The world’s largest heat pumps will be used for climate-friendly district heating generation in Aalborg, Denmark, in the successor to the Esbjerg heat pump project.

-

Long-duration energy storage from Oberhausen

In this interview, Hendrik Plate, Sales Manager for Energy Storage Solutions in Oberhausen, provides an outlook for MAN long-duration energy storage technology to supplement ETES

-

Materials testing pioneers

The Materials Test Laboratory in Hamburg is one of only a small number of facilities in Europe that can carry out tests close to absolute zero. With this capability, colleagues there are making an important contribution to hydrogen storage and transport.

-

A weld of difference

Colleagues at the Deggendorf site lead the world when it comes to building highly complex reactor systems.

-

We believe in the Augsburg site

The Executive Board has presented a four-stroke strategy that shows how the Augsburg site is going to be led into a successful future.

-

Four-stroke technology gets ready for methanol

In this interview, Petra Rektorik explains the development challenges that have to be overcome for four-stroke engines to be able to burn the future fuel methanol.