Colleagues at the Deggendorf site lead the world when it comes to building highly complex reactor systems.

Our employees possess valuable and unique expertise in the process engineering and assembly of highly complex reactor systems. Our customers, who come from a wide variety of industries, have been relying on our outstanding skills for decades.

Methanol synthesis in Chile

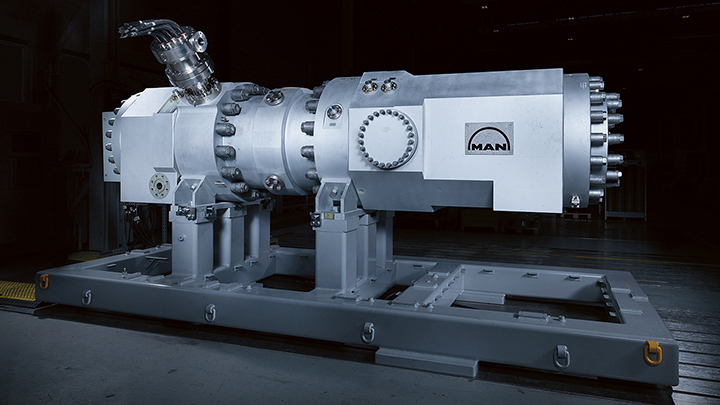

But reactors built in Deggendorf are used in much more spectacular projects. Among other things, MAN Deggendorf supplied the methanol synthesis reactor for the ‘Haru Oni’ e-fuel demonstration plant near the city of Punta Arenas in Southern Chile, which produces climate-neutral e-gasoline on behalf of Porsche AG. As a first step, the plant is employing wind power to make hydrogen, which is turned into methanol and finally e-gasoline.

Fusion energy in France

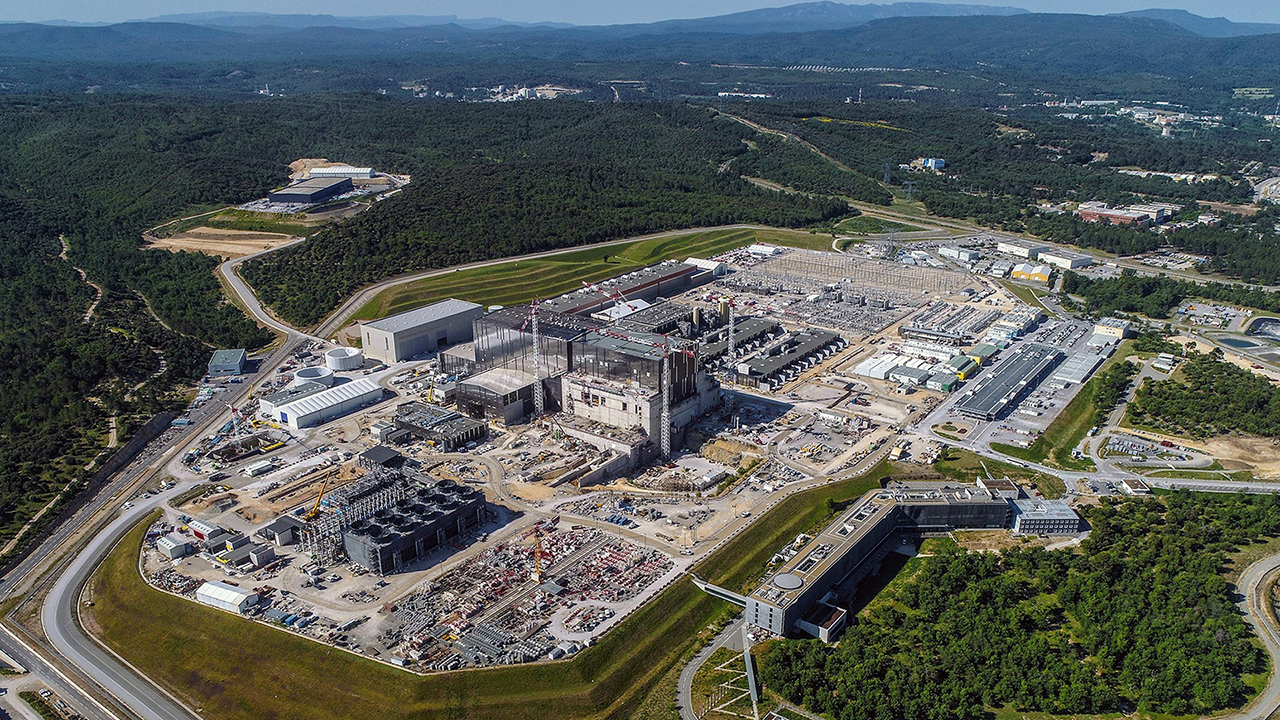

Specialists from Deggendorf are also involved in ITER, one of the most complex science and technology projects of all time. In Cadarache in the South of France, future energy generation will one day be revolutionized by means of a fusion reactor. MAN Deggendorf

is involved in building the facility’s centerpiece, the cryostat. The scale is vast: when fully assembled, the cryostat will be 30 meters high, weigh 3,850 metric tons and have a volume of 16,000 square meters. It is made up of 54 individual

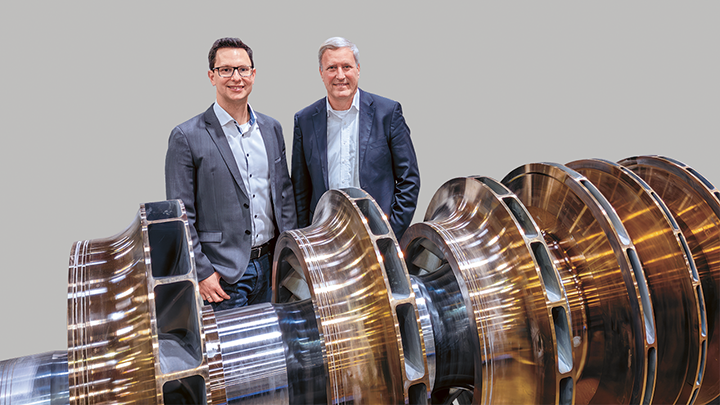

elements, which are being assembled and welded by 40 MAN experts – a process that will take 10 years in total. The work being done by the MAN specialists demands unparalleled accuracy: “We are working with the precision of a clockmaker

on components weighing thousands of metric tons,” says MAN Project Manager Andreas Binni. Which is why his people are constantly refining their assembly strategy and welding techniques as time goes by.

Head of Site Norbert Anger is rightly proud of his workforce: “Our employees possess valuable and unique expertise in the process engineering and assembly of highly complex reactor systems. Our customers, who come from a wide variety of industries, have been relying on our outstanding skills for decades.”

Explore more topics

The e-fuels revolution at the “End of the World”

Commissioned in December 2022 in the Southern tip of Chile, the Haru Oni demonstration plant could pave the way for a viable alternative to fossil fuels: It produces synthetic e-fuels from hydrogen that can help the fight against climate change. MAN Energy Solutions provided the e-methanol reactor to the plant.

Tomorrow's energy revolution

Thirty five nations; more than one million components assembled in factories around the world; over 20€ billion of investment; one of the most complex scientific and engineering projects ever seen: ITER (‘the way’ in Latin) is a project of superlatives. In southern France, a multinational cast of thousands is building the world’s largest tokamak, a magnetic fusion device that could change the future of sustainable energy production. And MAN is playing a major role.

-

Sustainable ammonia production

Ammonia can play a key role in decarbonization as a fuel and hydrogen carrier – MAN ES is very much at home with this chemical base material.

-

Sustainable fuels at competitive prices

A German startup wants to help cut carbon emissions in the mobility sector and is relying on the expertise of MAN Energy Solutions in Deggendorf to achieve its objective.

-

Engineering United

Cooperation between Holeby, Frederikshavn, Augsburg and Copenhagen crucial for the development of methanol genset.

-

Investment in testbeds

In a few years, our engines will be running on fuels like methanol and hydrogen, so we are already preparing our testbeds for the change.

-

Climate-neutral district heating for Denmark

The world’s largest heat pumps will be used for climate-friendly district heating generation in Aalborg, Denmark, in the successor to the Esbjerg heat pump project.

-

Long-duration energy storage from Oberhausen

In this interview, Hendrik Plate, Sales Manager for Energy Storage Solutions in Oberhausen, provides an outlook for MAN long-duration energy storage technology to supplement ETES

-

Materials testing pioneers

The Materials Test Laboratory in Hamburg is one of only a small number of facilities in Europe that can carry out tests close to absolute zero. With this capability, colleagues there are making an important contribution to hydrogen storage and transport.

-

We believe in the Augsburg site

The Executive Board has presented a four-stroke strategy that shows how the Augsburg site is going to be led into a successful future.

-

Four-stroke technology gets ready for methanol

In this interview, Petra Rektorik explains the development challenges that have to be overcome for four-stroke engines to be able to burn the future fuel methanol.