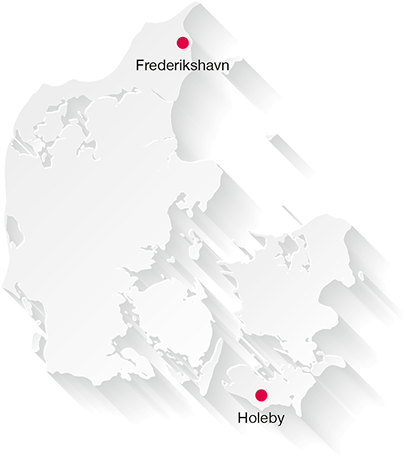

Cooperation between Holeby, Frederikshavn, Augsburg and Copenhagen crucial for the development of methanol genset.

There are few places in the Danish kingdom that are further away from Holeby than Frederikshavn. The team from Holeby's Test & Control department can attest to this. For the past year or so, they have been traveling on the E45/E47 between the two sites. Back and forth. A journey that will last throughout 2024 as well.

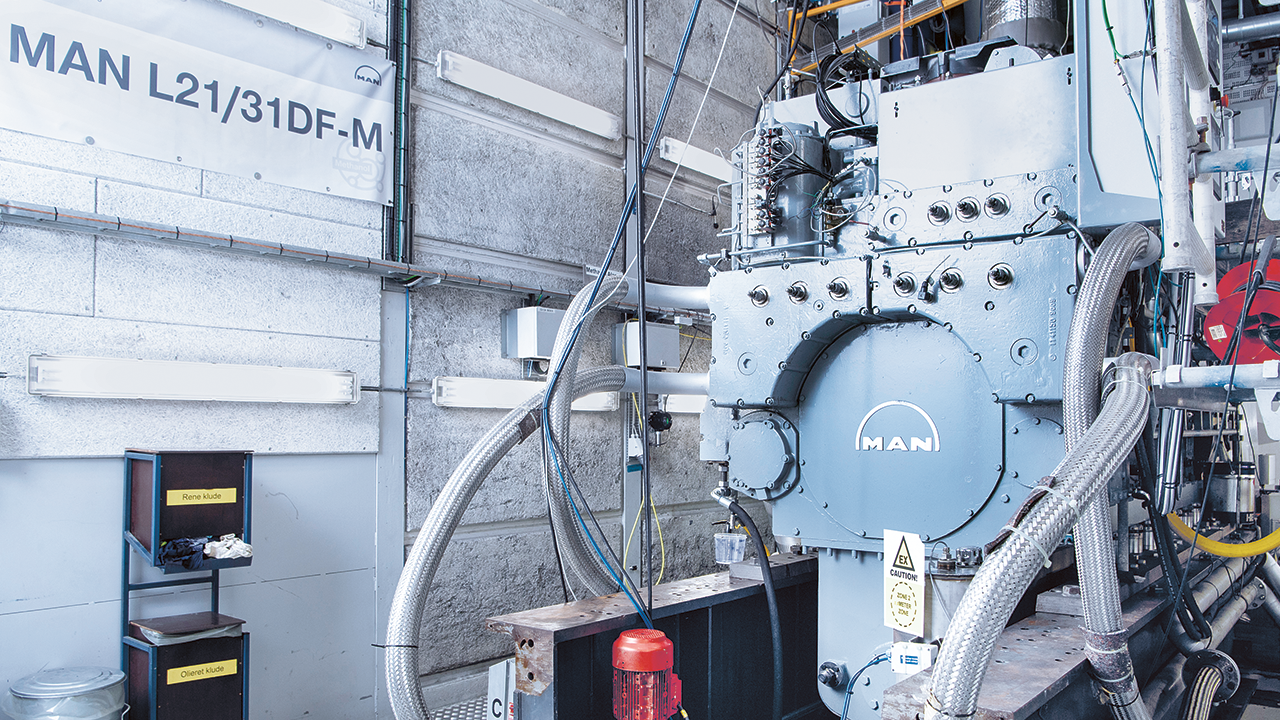

But the many road trips served an important purpose, namely so that the Holeby team could develop and test a MAN L21/31 that can run on conventional fuel, biofuels and green methanol, explains Michael Køel Andersen, Head of Four-Stroke Testing & Control, MAN Energy Solutions Holeby. In addition, the team was able to draw on input from Augsburg and Copenhagen.

"Collaboration was critical to the success of the project," Michael adds. "From Copenhagen, for example, we were able to use the same fuel valve train that had been used on the first methanol tests. We have inherited and rebuilt it so that it can be used on the four-stroke engines. So we have found common solutions and tried to bring in as much experience across the different technologies and engine types we have in the company."

Christian Kunkel, Head of Combustion Development in Augsburg, explains how his team contributed with early tests on a test bed in eastern Germany.

"We were approached about the project and did tests on a single-cylinder engine for this concept. We were able to share data on what the concept looked like and it was a very close collaboration," says Christian. "We discussed the next steps, and it was a lot of fun to derive a concept for and with the colleagues who are now driving in Frederikshavn. But not only my team made a great contribution for the development of the concept. Colleagues from the simulation department (EERPT), injection department (EERF) and the engine integration department (EEPSI) were of fundamental importance in developing the engine concept together with the colleagues in Denmark."

However, the conversion to methanol was not without its challenges, says Michael. "The biggest technical challenge was the adaptation of our control system SaCoS. But also how could we find space for injectors? How could the methanol system be integrated on the engine? The whole infrastructure is equipped with double-walled pipes and the external system with a fuel valve system and nitrogen purification. It was a huge challenge, but we found the solution."

The payoff came in the summer of 2023, when the team announced that the engine runs flawlessly on methanol.

Michael Køel Andersen

Collaboration was critical to the success of the project. We have found common solutions and tried to bring in as much experience across the different technologies and engine types we have in the company.

Ready for the tests of the future

Kim Nørgaard, Head of Test Center in Frederikshavn, also praises the collaboration. The introduction of methanol as a fuel instead of heavy fuel oil gave rise to a reorganization of the test facilities, he says.

"It has been an exciting task and also an honor to be involved in bringing four-stroke engines into the green technology, and that we can be part of that project. It is also something that motivates the crew in Frederikshavn," says Kim.

He adds that much of the methanol installation and infrastructure that was invested in will be used for testing other engines in the future.

"In this first installation, we have really tackled the green transition. We have removed any possibility of running heavy fuel oil. We're doing a green conversion of the tests. Heavy fuel oil is simply a thing of the past."

Hakon Juel Hansen

Ready for market

With the technical challenges solved, MAN now has a GenSet that can run on conventional fuel, biofuels and green methanol - an engine that is particularly well suited for ships with our methanol-powered main engine. The combination of a methanol GenSet and a methanol two-stroke engine provides clean power and propulsion for all parts of the vessel.

The market reception of the new GenSet is very positive, according to Hakon Juel Hansen, Promotion Manager & Business Development, Small-Bore GenSets in Copenhagen. More than 30 engines have already been ordered.

"Our teams have a lot of experience in bringing new fuel and engine technologies to market. In fact, we've been working with methanol-powered main engines for almost a decade now. We have drawn on this experience and applied years of knowledge to the methanol GenSets."

Hakon explains that the 21/31 engine already has a good reputation with over 110 million hours of operation.

"The team started with a very conventional design. Then we added the necessary components," says Hakon. "One of our competitors has developed a completely new methanol engine from scratch, which has presented enormous challenges and development costs. Our basic design is already well tested. It appeals to our customers that our concept is simple and reduces capex. At the same time, customers know that they won't be sailing on methanol tomorrow. They might do it in 5, 10 or 15 years, so they are ready for the future."

Michael says: "It's a great example of interdisciplinary collaboration between development and design across national borders and internally across departments. It's a full circle."

With Port Fuel Injection, the engine can deliver fuel safely at low pressures and reduce customers' capital expenditure

Explore more topics

-

Better than reality

As a virtual and augmented reality developer at the Augsburg site, Carolin Lirsch sees to it that we can exploit the possibilities offered by virtual technologies profitably for ourselves and our customers.

-

Reducing its own footprint

In the SCOUTHEAT project, all the engineering disciplines in Oberhausen are breaking new ground – the close cooperation enables nearly autonomous machine operation.

-

Where a talent for communication meets optimism

Cary Cao has worked for MAN ES in China for nearly 20 years, for the last two as Team Leader Contracts & Project Management Four-Stroke China. In this interview, she talks about her career, what she loves about her job and her personal recipe for success.

-

Methanol readiness is vital

In this interview, Marita Krems, Head of Four-Stroke Marine & License, talks about different customer requirements and her highlight projects.

-

Short response times low emissions

Gas power plants can provide backup for renewable energies, yet investments in this type of energy generation have faltered in recent years. What are the reasons for this and how will the market evolve?

-

Obsolescence logged off

Obsolescence poses a major challenge for industry going forward, threatening to test the limits of equipment durability and customer satisfaction.