The Executive Board has presented a four-stroke strategy that shows how the Augsburg site is going to be led into a successful future.

Fossil fuels are past their sell-by date

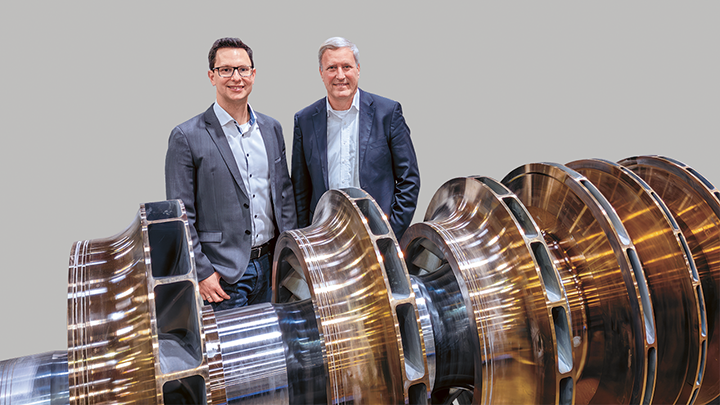

Although the combustion engine is far from being past its sell-by date, the fossil fuels that have powered our engines until now definitely are. Heavy fuel oil, diesel & Co. will have to make way for climate-neutral fuels like synthetic natural gas, methanol and, looking further ahead, ammonia and hydrogen. Chief Technology Officer Gunnar Stiesch outlines the way forward: “Methanol is emerging as the future fuel of choice in the four-stroke segment. In R&D, we are working intensely on methanol-ready engines, which should be available by 2027 at the latest. At the same time, we are preparing the technology for burning ammonia and hydrogen in our engines, something that is particularly relevant for power generation.”

Recapturing markets

We have been working on using new fuels in our four-stroke engines for some time now. That is not enough, however. The Executive Board has come up with a four-stroke strategy for the Augsburg site that involves all relevant areas from Sales to Production. “The markets are recovering following the Covid years and we want a share in this upturn. The task is to utilize our production facilities in Augsburg to capacity once more. When it comes to shipping, the cruise ship, ferry and government vessel markets are particularly promising. In the case of energy generation, we are concentrating on the balancing power market and so-called baseload power plants,” says Uwe Lauber, describing the strategy objectives. As Chief Sales Officer, he is at the forefront of landing corresponding orders together with colleagues in Marine and Power Sales. Although competition is tough, colleagues want to stand up to our competitors and recapture market shares.

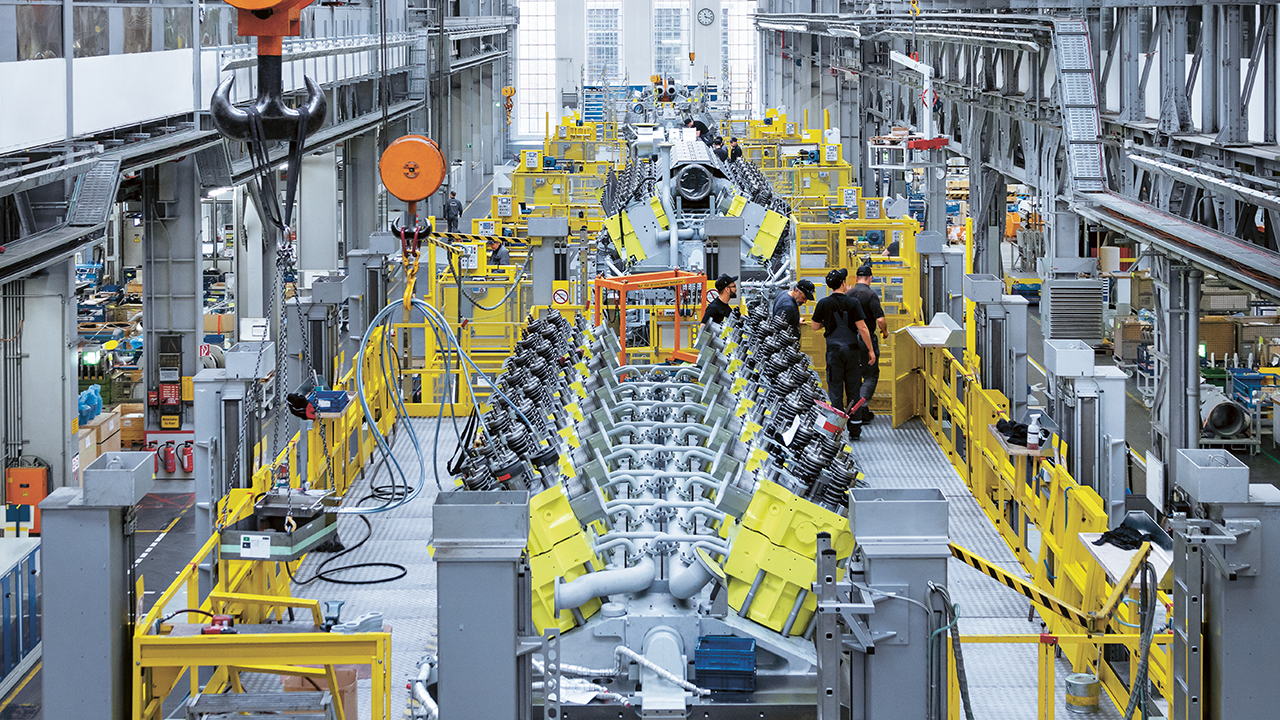

In recent years, we have invested millions in production and machinery in Augsburg, and will continue to do so.

Hopes pinned on MAN 49/60DF

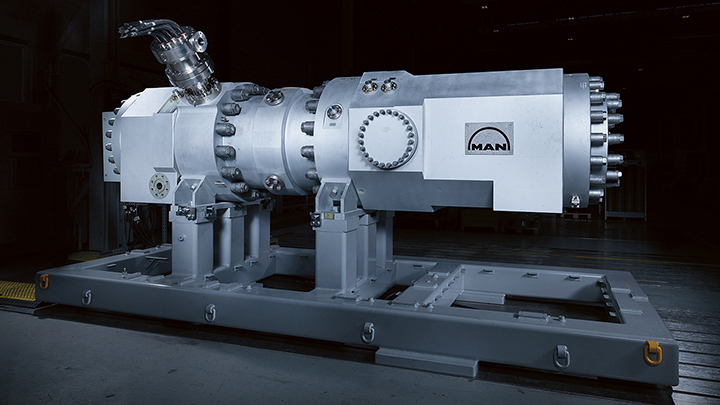

Special attention is being paid to the new 49/60DF engine, for which there are high hopes. It has the best efficiency and power density in its class, is equipped with the latest MAN technologies and offers minimized methane slip. Reference customers have been found for both Marine and Power, so the engine will now be able to prove itself in the market too. The 3X series is also going to see further development. The aim is to create a future-proof platform for alternative fuels in Marine on the basis of our tried and tested 32/44CR by integrating our latest turbocharger and injection technologies.

Colleagues received information on the four-stroke strategy for the Augsburg site straight from the horse’s mouth at department-specific town hall meetings

Component production supports capacity utilization

But green engines employ far more technologies that we developed at the Augsburg site and produce there too. This too contributes to capacity utilization in our production. Examples of key components made in Augsburg include the 2.2 common rail system, the injection systems for methanol engines, the new SaCoS5000 engine control system, two-stage turbocharging and the next generation of adaptive combustion control, ACC 2.0. The same applies to MAN PrimeServ’s spare parts, which have been ensuring high capacity utilization in Augsburg for years now. Converting existing engines to new fuels is a profitable business activity that we are pursuing energetically. There are thousands of four-stroke engines in ships and power plants with retrofit potential. We want to convert this fleet so that new fuels can be used.

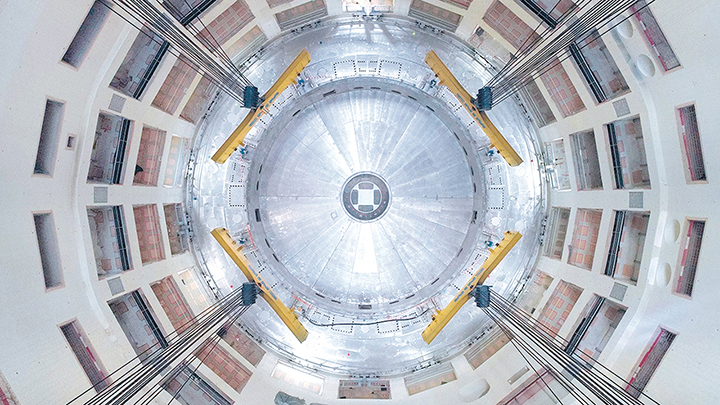

Millions in investment

“In recent years, we have invested millions in production and machinery in Augsburg, and will continue to do so,” says Martin Oetjen who is responsible for Production and Supply Chain on the Executive Board. Examples include the testbeds and associated media preparation station, the installation of hydrogen infrastructure, and the new machine tools in Turbocharger Production and Component Production. “We believe in the site and want to lead it into a successful future,” says Martin Oetjen, giving the bottom line.

New skills wanted

The Training Center has also undergone a comprehensive technical upgrade and been outfitted with new machinery. This is important when it comes to training the young people who enter the workforce at MAN Energy Solutions and preparing them for future challenges. “One thing is clear: if we are to achieve our objectives, we will need new skills. We take account of this in our training, while at the same time looking specifically for personnel for those areas that are vital for the successful implementation of our strategy,” Chief Human Resources Officer Martin Rosik points out.

“We still have grand plans for the future”

All this is not to be had for nothing, of course, but MAN Energy Solutions is on the right track thanks to the systematic implementation of the Performance 2023 program for the future. Our company achieved record order intake of over EUR 4 billion in 2022. And operating return has effectively already reached the 9 percent target. Chief Financial Officer Jürgen Klöpffer sums up our objectives: “We still have grand plans for the future, so it is vital that we have a sound and secure financial basis – to provide a foundation for our strategy and fuel for our growth.”

Both Assembly and Component Production will benefit from the four-stroke strategy in the long term

Explore more topics

-

Sustainable ammonia production

Ammonia can play a key role in decarbonization as a fuel and hydrogen carrier – MAN ES is very much at home with this chemical base material.

-

Sustainable fuels at competitive prices

A German startup wants to help cut carbon emissions in the mobility sector and is relying on the expertise of MAN Energy Solutions in Deggendorf to achieve its objective.

-

Engineering United

Cooperation between Holeby, Frederikshavn, Augsburg and Copenhagen crucial for the development of methanol genset.

-

Investment in testbeds

In a few years, our engines will be running on fuels like methanol and hydrogen, so we are already preparing our testbeds for the change.

-

Climate-neutral district heating for Denmark

The world’s largest heat pumps will be used for climate-friendly district heating generation in Aalborg, Denmark, in the successor to the Esbjerg heat pump project.

-

Long-duration energy storage from Oberhausen

In this interview, Hendrik Plate, Sales Manager for Energy Storage Solutions in Oberhausen, provides an outlook for MAN long-duration energy storage technology to supplement ETES

-

Materials testing pioneers

The Materials Test Laboratory in Hamburg is one of only a small number of facilities in Europe that can carry out tests close to absolute zero. With this capability, colleagues there are making an important contribution to hydrogen storage and transport.

-

A weld of difference

Colleagues at the Deggendorf site lead the world when it comes to building highly complex reactor systems.

-

Four-stroke technology gets ready for methanol

In this interview, Petra Rektorik explains the development challenges that have to be overcome for four-stroke engines to be able to burn the future fuel methanol.