Ammonia can play a key role in decarbonization as a fuel and hydrogen carrier – MAN ES is very much at home with this chemical base material.

As a carbon-free medium, green ammonia is attracting a great deal of attention – in addition to fertilizer production, it is also used as a future fuel in shipping and as a hydrogen carrier. “MAN Energy Solutions has decades of experience and represents the entire value chain for manufacturing ammonia in terms of turbomachinery,” says Markus Schürmann, Sales Manager and Project Developer Green Ammonia. “The processes are tried and tested. Switching from fossil fuels to green hydrogen is changing the boundary conditions, however. We’re seeing a lot of interest and a great need for advice on the part of customers, with forecasts assuming a trebling of global capacity.”

What is MAN ES’s contribution

to ammonia production?

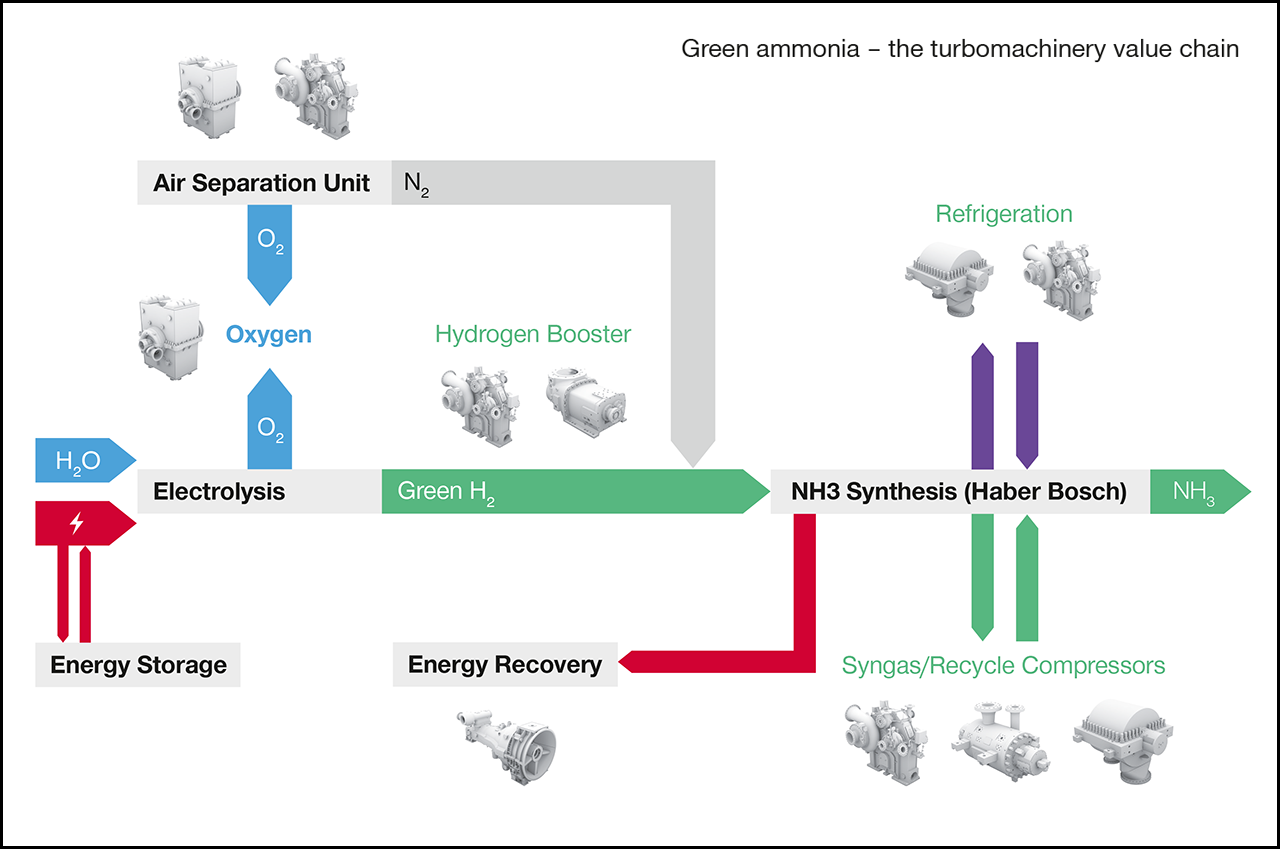

Nitrogen (N2) is obtained on an industrial scale by means of air separation, for which various compressor types are used, including isothermal (RIKT) and integrally geared (RG). In future, green hydrogen (H2) can also

be produced by electrolysers from H-TEC SYSTEMS. When it comes to further compression of the hydrogen, screw and centrifugal compressors (RG/RB) are also used. The nitrogen and hydrogen are then compressed to a high pressure in an RB/RH synthesis gas compressor and turned into NH3 in the reactor. An RH/RG refrigeration compressor then cools the hot ammonia. MAN also offers other solutions that could be used to boost the efficiency of processes, such as expansion turbines for energy recovery, heat pumps for process heat generation and energy storage systems. Oxygen compressors (RIKT/RG) can be used to exploit the oxygen generated by the process.

“Ammonia offers advantages for shipping and power generation: it’s CO2-free when burned and can also be used as a comparatively cheap carrier for large quantities of hydrogen. The infrastructure for ammonia transport already exists, and blue ammonia (ammonia produced from hydrocarbon feedstock with carbon dioxide capture by means of CCUS) is already seeing rapid expansion. NEOM, the first commercial green ammonia plant, will be followed by others in the medium term,” says Andreas Kramer, Business Development Manager.

MAN Energy Solutions has decades of experience and represents the entire value chain for manufacturing ammonia in terms of turbomachinery.

Explore more topics

At the frontier of ammonia propulsion

Having developed a range of dual-fuel engines for greener fuels, MAN Energy Solutions' Research Centre Copenhagen (RCC) is pursuing the next milestone in achieving net-zero shipping: the first two-stroke ammonia marine engine. It's the story of how a toxic and pungent smelling chemical can make shipping greener.

-

Zurich compressor technology minimizes footprint

MAN ES is supplying two electric HOFIM® compressor systems for gas storage facilities in Italy – Zurich’s state-of-the-art compressor technology will help to reduce emissions.

-

An important investment in the Augsburg site

A state-of-the-art system for processing cylinder heads is currently being put into operation in Augsburg – a further contribution to securing the site’s future.

-

Milestone for green hydrogen economy

Quest One – formerly H-TEC SYSTEMS – is going to manufacture PEM electrolysis stacks in Hamburg using highly automated series production. These will play a key role in ramping up the hydrogen economy.