Quest One – formerly H-TEC SYSTEMS – is going to manufacture PEM electrolysis stacks in Hamburg using highly automated series production. These will play a key role in ramping up the hydrogen economy.

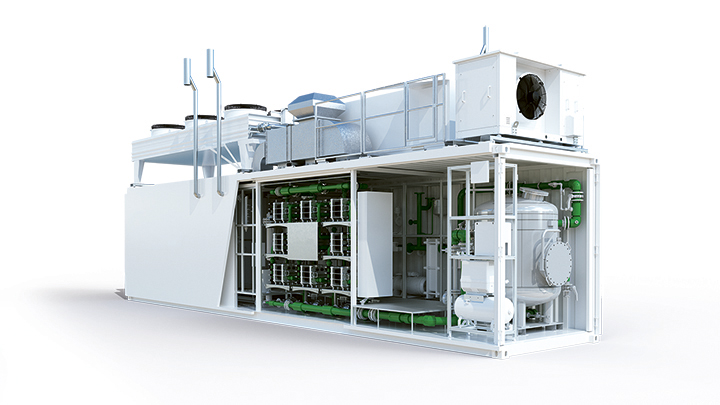

Quest One’s state-of-the-art production plant in Hamburg officially commenced operations in late September 2024. The Gigahub, as it is called, will develop, produce and test stacks for PEM electrolysis in nearly 11,000 square meters of space. Stacks are the technological heart of electrolyzers, splitting water into oxygen and hydrogen using renewable electricity. As a result, they will play a key role in ramping up the future hydrogen economy. PEM electrolysis, which is based on proton exchange membrane technology, is one of the most important processes for industrial-scale hydrogen production using renewable energies. “This state-of-the-art facility takes us a huge step closer to achieving our company goal of preventing one percent of global greenhouse gas emissions by 2050 through use of our electrolyzers,” Robin von Plettenberg, CEO of Quest One, points out.

‘Gerd’ assembly line with swing-arm robots

Production time less than an hour

When expansion is complete, automated series production of PEM stacks with a potential total electrolysis capacity in excess of 5 gigawatts a year will be possible at the Gigahub. The stacks can now be produced in less than an hour in Hamburg. Two assembly lines are being used for this purpose: ‘Titan’ with a linear transport system and ‘Gerd’ with swing-arm robots – both in a cleanroom environment. The lines are named after two moons of the planet Saturn, which is around 95 percent hydrogen. With two different stacking technologies to choose from, Quest One wants to determine which process is most suitable for series production.

Ultramodern workstations for 430 people

The Gigahub’s office facilities are designed to accommodate 320 people, while up to 110 people per shift can work in production and the laboratories. Quest One currently employs more than 200 people in Hamburg and Braak. Ten percent of the workstations are accessibly designed for people with disabilities. Quest One sets great store by employees enjoying a perfect environment, including good links to local public transport as well as parking for cycles and e-bikes, not to mention a gym, a library and flexible childcare. In addition, Quest One is aiming to achieve Platinum Certification by the German Sustainable Building Council in 2025.

Right at the forefront in future

Robin von Plettenberg is in no doubt: “The hydrogen economy will change massively in the next few years and green hydrogen will be required in quantities that we can scarcely imagine today. The electrolysis industry will spearhead this sunrise sector. That is why, with our Gigahub in Hamburg, we have created the conditions that will enable us to be right at the forefront in future.”

Explore more topics

About Quest One

Quest One (former H-TEC SYSTEMS) is a global leader in the field of PEM electrolysis. The company develops and produces innovative electrolyzers and electrolysis stacks for the economical, efficient and reliable production of green hydrogen. Quest One's declared goal is to make a significant contribution to the fight against climate change with its own products. The company's mission is to avoid one percent of global greenhouse gas emissions by 2050 through the use of its electrolyzers.

-

Zurich compressor technology minimizes footprint

MAN ES is supplying two electric HOFIM® compressor systems for gas storage facilities in Italy – Zurich’s state-of-the-art compressor technology will help to reduce emissions.

-

An important investment in the Augsburg site

A state-of-the-art system for processing cylinder heads is currently being put into operation in Augsburg – a further contribution to securing the site’s future.

-

Power-to-hydrogen for Finland

MAN ES is building a production plant for green hydrogen in Helsinki together with Quest One.