It is Carolin Wußmann-Kunz’s job to protect MAN ES against the liability claims that can result from defective products. We explain how the lawyer does that and what she finds fascinating about her job.

Product liability refers to a manufacturer’s liability for personal injury and property damage resulting from use of a defective product. “As soon as we as a company learn of a potential product defect for which we bear responsibility, we have to remedy it as quickly as possible,” lawyer Carolin Wußmann-Kunz, Head of Group Legal Product Liability, explains. “If we fail to do so, the penalty in the worst case is prison.” It is her task to ensure that, in such cases, MAN ES warns customers about any risk and is on the safe side legally.

Analysis by various bodies

The main authority in this area at MAN ES group level is the Product Safety Committee (APS), which the lawyer has established over the past decade in collaboration with colleagues from Technology, Quality and Service. If it becomes apparent that there is a defect in our equipment or engines that represents a danger to life and limb, that could result in a substantial loss for MAN ES or damage to its image, or that means rules or statutory provisions are no longer being complied with, the matter must be reported to the APS Clearing Board without delay. If the risk exceeds a certain level, the next step is to convene the APS, which is made up of around 20 experts representing the various departments, from Quality Management, through Development and PrimeServ, to Communication. Working together, they analyze the causes of the reported defects, the risks the defects present, a possible technical solution and whether it might even be necessary to recall the product. Customers who use the engines or equipment of the type in question are then informed accordingly in a warning letter about the risks and the action being taken.

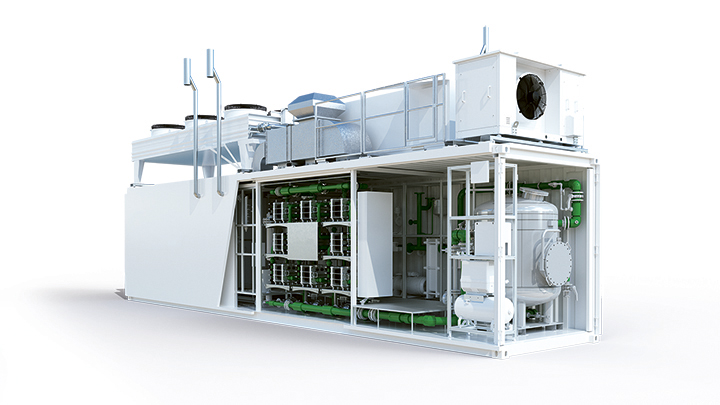

Around 50 such cases a year land on Carolin Wußmann-Kunz’s desk or are referred to the Product Safety Committee – and the figure is rising. This is due to expansion into new areas of business, such as the electrolysis technology of subsidiary H-TEC Systems GmbH. Defects are caused by a number of issues, from material fatigue, through incorrect operation by the customer, to the use of defective components by suppliers or actual design faults. “We carry out extensive quality checks, of course, and test our products before delivering them to the customer. But with new products in particular – gas engines, for example – defects sometimes only show up in the field, that is to say when the engine or equipment is being used by the customer in real-life conditions,” Carolin Wußmann-Kunz explains.

In the event of a concrete problem, the committee decides what MAN ES will do on a case-by-case basis, always taking the imminent risk situation into account, of course. A product recall is necessary in around a third of cases. With ship engines, the customer can usually continue using the engine at reduced load and put in at the next port, where MAN PrimeServ will carry out the repair. Turbine defects are much more critical, as they present a higher risk by virtue of the speed at which turbines rotate. In such cases, the system may have to be shut down completely until it has been repaired.

As soon as we as a company learn of a potential product defect for which we bear responsibility, we have to remedy it as quickly as possible.

MAN ES turbochargers set safety standards

“Every product recall places us under an obligation to return the product to a safe condition, in other words make it safe. In the process, we further refine our products,” says Carolin Wußmann-Kunz. “That’s why we do extensive testing and, where possible, also use computer simulations when working out a redesign.” Turbochargers provide a good example of what this means: MAN ES worked intensively on its turbochargers in response to past recalls, with the result that the company now sets the safety standards for the entire industry in this field.

No off-the-peg approach

Alongside ‘tangible’ defects like this, the 46 year old is also concerned at present with the issue of cyberattacks, which can trigger dangerous incidents: “We’re grappling intensively with the issue, although the relevant EU guidelines have not yet been published in their final form. That complicates matters even further, but we’re working in close synch with our Chief Information Security Officer.” This is an excellent example of what the lawyer likes so much about her job: current developments, new products and new areas of business for MAN ES always bring new challenges, like getting into hydrogen technology, new fuels for engines or industrial heat pumps. The technical background plays an important role in all this, but not all the details are relevant for Carolin Wußmann-Kunz. “The engineers go into extreme depth with their defect analysis, of course,” she says. “But I’m far more interested in assessing the risk situation and the question of how long it will take to find a technical solution, plus what legal – and in some cases practical – steps have to be taken in order to make things safe as quickly as possible. Every case really is different, there is no off-the-peg approach. That’s what I find so fascinating about my job and stops it from ever becoming boring!”

Explore more topics

-

Zurich compressor technology minimizes footprint

MAN ES is supplying two electric HOFIM® compressor systems for gas storage facilities in Italy – Zurich’s state-of-the-art compressor technology will help to reduce emissions.

-

An important investment in the Augsburg site

A state-of-the-art system for processing cylinder heads is currently being put into operation in Augsburg – a further contribution to securing the site’s future.

-

Milestone for green hydrogen economy

Quest One – formerly H-TEC SYSTEMS – is going to manufacture PEM electrolysis stacks in Hamburg using highly automated series production. These will play a key role in ramping up the hydrogen economy.

-

Power-to-hydrogen for Finland

MAN ES is building a production plant for green hydrogen in Helsinki together with Quest One.

-

Sustainable ammonia production

Ammonia can play a key role in decarbonization as a fuel and hydrogen carrier – MAN ES is very much at home with this chemical base material.

-

Investment in testbeds

In a few years, our engines will be running on fuels like methanol and hydrogen, so we are already preparing our testbeds for the change.