European premiere: Additional new 3D printer boosts MAN ES’s additive manufacturing capacity at Oberhausen site.

The new geometric freedom makes it possible to further optimize designs in terms of availability, performance, lifespan and maintenance.

Dawn of a new additive era

Owing to the high degree of product variance, the possibilities offered by metallic 3D printing for MAN ES are virtually unlimited. “Until now, the enormous potential far exceeded the available manufacturing capacity,” Anders Such, Head of Additive Manufacturing in Oberhausen, explains. Expanding our in-house manufacturing capacity will broaden the component spectrum, and the new print bed size of 600 mm in all three dimensions will make it possible to manufacture small housings additively, cutting their delivery time by up to a factor of four at the same cost. Twelve 1,000-watt lasers operating in parallel see to it that the new printer manufactures components eight times faster than the 280 (with its two 400-watt lasers). This makes the SLM 600 the most productive 3D printer for LPBF (Laser Powder Bed Fusion).

‘Think additive’ – boost for research and development

MAN’s additive know-how expands with every component, and the possibilities also make a leap with every printer generation. “The productivity boost and larger print bed volume are extending the range of potential applications,” Michael Kleinhenz, Head of Production and Supply Chain, explains. “The new printer is being used both to manufacture existing business cases more economically and to industrialize further applications.” Anders Such lists other advantages that AM offers in addition to the cost benefits: “The new geometric freedom makes it possible to further optimize designs in terms of availability, performance, lifespan and maintenance.” As one of many more examples at MAN, AM is used in integrally geared compressors. What is more, manufacturing process development is currently in progress on additively manufactured impellers for hot gas expanders in Industries.

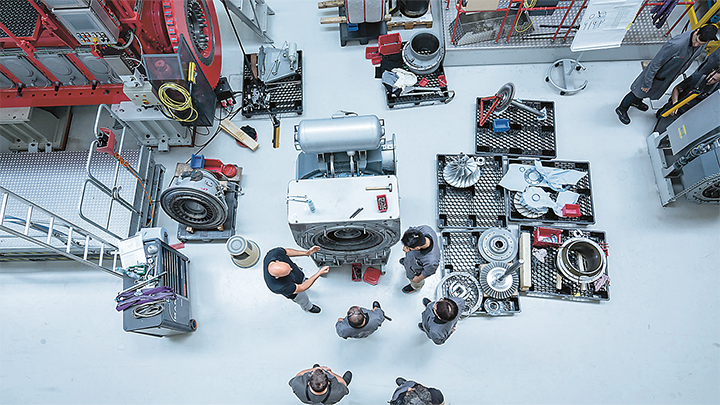

At MAN ES, LPBF is currently used to make machine parts for compressors (resonators), turbines (impeller segments, combustion chambers), two-stroke engines (precombustion chambers), turbochargers (damper elements) and four-stroke engines (injection nozzles, precombustion chambers). This means that AM now covers our entire range of machinery in Newbuild and Service.

Explore more topics

-

Five technologies for aclimate-neutral future

By 2030, we want to generate most of our revenue with climate-neutral technologies. How do things currently stand?

-

Large-scale heat pumps

By 2030, we want to generate most of our revenue with climate-neutral technologies. How do things currently stand?

-

-

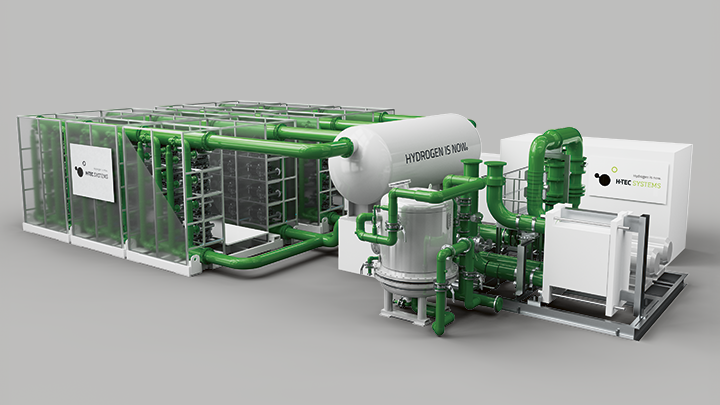

Hydrogen Power-to-X

By 2030, we want to generate most of our revenue with climate-neutral technologies. How do things currently stand?

-

-

Green engines

By 2030, we want to generate most of our revenue with climate-neutral technologies. How do things currently stand?

-

A look at the regions

MAN Energy Solutions has more than 120 locations around the world. We manage our global activities in the regions. How do our colleagues in the Americas, Asia Pacific, Europe and Middle East Africa regions live the corporate strategy? How do they approach customers? And which products have the greatest opportunities where? This feature provides the answers.

-

A wide variety of opportunities for our focus technologies

Which of our products are in particular demand in the Americas, Europe, Middle East Africa and Asia Pacific regions? And how can MAN Energy Solutions contribute to decarbonization in the various parts of the world? We asked the Heads of Region.

-

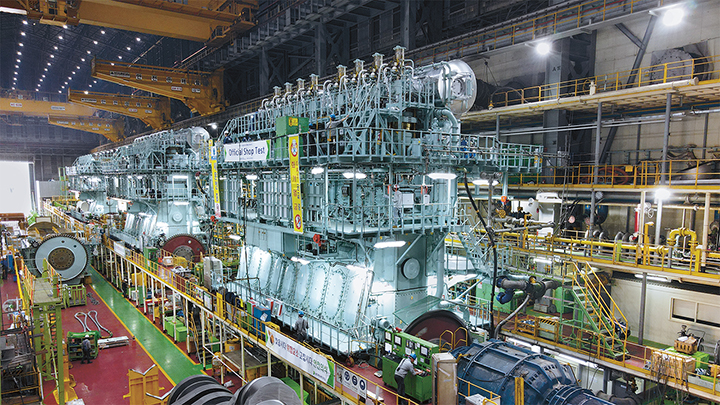

Experience sharing in South Korea

In mid-September 2023, MAN Energy Solutions invited its licensees from all over the world to South Korea. The focus was not just on a mutual exchange of ideas on technical issues, but on making a joint commitment to sustainability and climate protection.

-

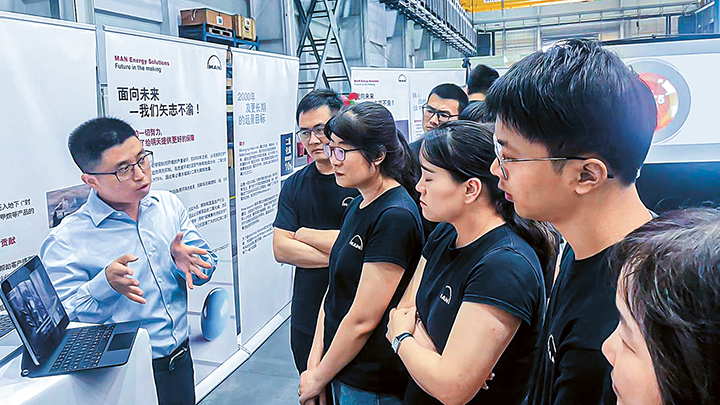

Making our corporate strategy tangible

‘Future Fairs’ were held at all MAN Energy Solutions’ production sites in 2023 and met with great interest from colleagues.

-

Making sense of digital competencies

Machines that are operated autonomously. 3D printers that open up entirely new manufacturing possibilities. And artificial intelligence that reduces workloads and thus frees up capacity.

-

MAN revolutionizes gas production again

Following innovative subsea compression, MAN ES is once more setting a new industry standard in gas production, with semi-autonomous machine operation giving sustainability and efficiency a further boost.

-

With AI we can prioritize the important stuff

AI tools like ChatGPT have been grabbing the headlines for months. MAN People asked experts from Group IT, PrimeServ Marine and Information & Cyber Security to give their assessment of this technology.

-

Every little bit helps

MAN Energy Solutions has been pursuing concrete climate goals for its production sites for many years already. Christoph Zeppenfeld and Dietmar Pinkernell explain where we are now and what is planned for the period up to 2030.

-

Tiny molecules with enormous potential

In this interview, hydrogen expert Professor Christopher Hebling explains why there is no getting around green hydrogen as a fuel.