Our turbochargers are built at three sites, each of which has a clearly defined product portfolio. Instead of the internal competition that often ruled in the past, the emphasis now is on mutual support. A current example shows how it works.

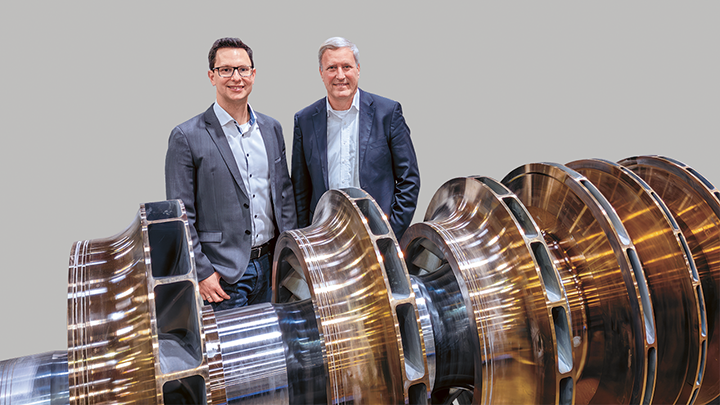

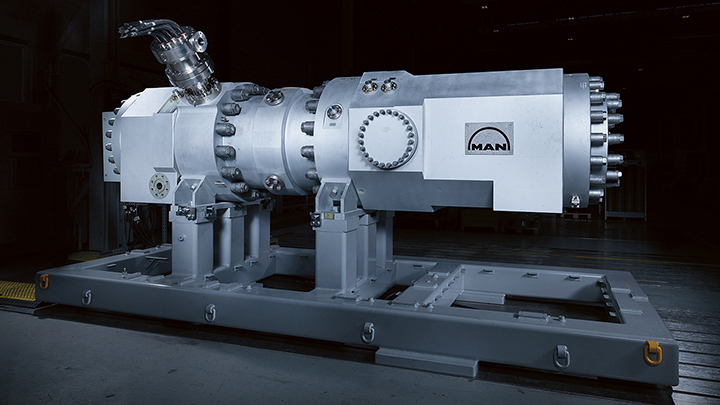

All told, 226 colleagues work at PBST Turbo in Velká Bíteš, which has been part of the MAN family since 1997. Its portfolio encompasses turbochargers for use in ships, power plants or even locomotives, for example. Colleagues there carry out development and production autonomously, but are still part of a strong network within MAN Energy Solutions. “We’ve continuously expanded and intensified our cross-site cooperation over the years,” says Mirko Petrović, Head of Turbocharger Production in Augsburg. Alongside Augsburg and Velká Bíteš, the third member of the production network is Changzhou in China. The clear allocation of products was an important step in avoiding internal competition and building mutual trust. Whereas Augsburg manufactures big turbochargers with an output of up to 30,000 kW, Velká Bíteš builds smaller models with an output of 390 kW to 2,700 kW per turbocharger. Changzhou procures turbocharger housings locally and assembles TCT series turbochargers for the Asian market. The three sites are very willing to help each other out, as a recent example demonstrates.

Joint solution for the customer’s benefit

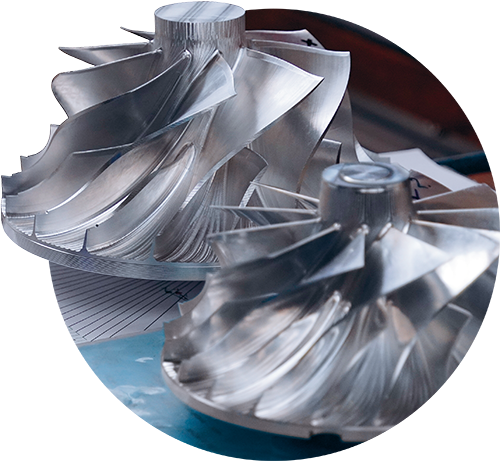

Last year, a customer requested significantly more turbochargers from Velká Bíteš than originally planned. This put the site in a tight spot, as production was at full capacity and there was no leeway to increase it further at will. Mirko Petrović and Josef Malý, PBST Turbo’s Managing Director, therefore looked together for some way to give the customer what they wanted. “Simply increasing production was not an option, but we found ways in which more turbochargers could be built in the same time,” Josef Malý explains. This included both expanding outsourcing for Velká Bíteš and reducing processing times for compressor wheels in collaboration with Augsburg. To this end, specialists from Turbocharger NC Programming in Augsburg traveled to the Czech Republic and helped on the spot. They used special software to analyze the existing NC programs with a view to cutting the production time for compressor wheels by up to 35 percent. This allowed more compressor wheels to be manufactured with the same plant capacity, as well as generating annual savings of EUR 250,000. “The colleagues visited Velká Bíteš several times between October 2023 and January 2024. Meanwhile, two colleagues in Augsburg had their backs and took care of their work for them,” Bernd Riebler, Head of Turbocharger NC Programming Augsburg, explains. The full optimization was completed at the end of March 2024.

New CAD/CAM software introduced in Production

Mirko Petrović is keen to stress that the support is not all in one direction, however: “Colleagues in Velká Bíteš are one step ahead when it comes to using Siemens NX, special CAD/CAM software. In this instance, we were able to benefit from their experience and expertise here in Augsburg.” This specific case, for example, involved a direct interface between Design and the CAD/CAM software in Production that Augsburg was able to adopt from Velká Bíteš and so save EUR 100,000. Methods that have already been put to the test in Velká Bíteš and become well established ultimately led to success in Augsburg as well.

We’ve continuously expanded and intensified our cross-site cooperation over the years.

Close collaboration going forward too

Mirko Petrović and Josef Malý are in agreement: trust is the basis on which such successes can be achieved. They therefore encourage employees to visit each other so as to bolster personal contact and communication. But people have to be open to accepting new things at every level – which means both employees and managers. Mirko Petrović stresses that close collaboration is essential for the future too: “There are so many issues where both sides can benefit if we tackle them together. I’m thinking of processing strategies, measurement techniques or tool and automation concepts. We will not run out of ideas.”

Changzhou

Changzhou is really a turbomachinery site. In order to exploit synergies in the Asian market, the decision was taken in 2020 to also assemble TCT series turbochargers for two-stroke applications there, and to procure components locally and therefore more economically. The important thing is that the ‘heart’ of the turbocharger, the rotor assembly, comes from Augsburg, while the housings are bought in locally. The ramp-up is now complete, with 60 superchargers being successfully delivered to our customers in 2023. The plan is to assemble around 110 superchargers a year in Changzhou.

Explore more topics

Creating a cleaner fuel

Renewable synthetic fuels like synthetic natural gas and methanol are pivotal in decarbonizing the economy, with potential applications in industrial processes, chemical manufacturing, shipping and much, much more. Discover takes a peek inside the processes and technologies that are helping to bring these fuels to the world.

The benefits of methanol

With Maersk’s order of the world’s first container vessel fueled by carbon-neutral methanol, the fuel’s use is likely to gain momentum as maritime shipping transitions to become a greener industry. But what are its real advantages? MAN Energy Solutions’ fuel and two-stroke expert Kjeld Aabo tells us why methanol is so attractive.

-

Sustainable ammonia production

Ammonia can play a key role in decarbonization as a fuel and hydrogen carrier – MAN ES is very much at home with this chemical base material.

-

Sustainable fuels at competitive prices

A German startup wants to help cut carbon emissions in the mobility sector and is relying on the expertise of MAN Energy Solutions in Deggendorf to achieve its objective.

-

Engineering United

Cooperation between Holeby, Frederikshavn, Augsburg and Copenhagen crucial for the development of methanol genset.

-

Investment in testbeds

In a few years, our engines will be running on fuels like methanol and hydrogen, so we are already preparing our testbeds for the change.

-

Climate-neutral district heating for Denmark

The world’s largest heat pumps will be used for climate-friendly district heating generation in Aalborg, Denmark, in the successor to the Esbjerg heat pump project.

-

Long-duration energy storage from Oberhausen

In this interview, Hendrik Plate, Sales Manager for Energy Storage Solutions in Oberhausen, provides an outlook for MAN long-duration energy storage technology to supplement ETES

-

Materials testing pioneers

The Materials Test Laboratory in Hamburg is one of only a small number of facilities in Europe that can carry out tests close to absolute zero. With this capability, colleagues there are making an important contribution to hydrogen storage and transport.

-

A weld of difference

Colleagues at the Deggendorf site lead the world when it comes to building highly complex reactor systems.

-

We believe in the Augsburg site

The Executive Board has presented a four-stroke strategy that shows how the Augsburg site is going to be led into a successful future.

-

Four-stroke technology gets ready for methanol

In this interview, Petra Rektorik explains the development challenges that have to be overcome for four-stroke engines to be able to burn the future fuel methanol.